Product Detail

Building upon the global success of the Falath Evo, Elves Bikes research and development team have launched their latest aero frame, the Falath EXP utilizing next-generation industry technology, with a focus on shock-absorbing performance, comfort, strength and aerodynamic efficiency.

At the core of the Falath EXP’s design philosophy sits an integrated aerodynamic suspension design of the rear seat stay. A topology optimization algorithm is employed for frame structural design which simultaneously optimizes both aerodynamic performance and suspension capabilities.

The Inverted Triangle Airflow Channel (ITAC), is a meticulously engineered rear triangle that is formed by the seat stay and seat tube creating an airflow channel that minimizes wind resistance, reduces drag coefficient and turbulence, allowing riders to achieve improved overall performance.

Beyond aerodynamics, the inverted triangle structure creates controlled vertical flexible movement of the integrated seat post, whilst retaining superior structural strength, stability and stiffness distribution across the frame. In real world riding, this vertical movement is designed to absorb road vibrations, especially on uneven terrain, resulting in a smoother, more comfortable riding experience without the requirement to compromise stiffness & performance by incorporating unnecessary flex into the wider frame. To further enhance the EXP’s rider appeal, the frame has been designed with tyre clearance of up to 32c providing enhanced grip, comfort and speed on today’s roads.

Engineered with high-tensile Japanese Toray T800 carbon fiber, reinforced with T1000 in key performance areas such as the bottom bracket and headtube, and combined with its inverted triangle structure, the Falath EXP has been designed to optimize stress distribution, durability, aerodynamics and overall stiffness, resulting in superior power transfer in high-intensity riding conditions. To enhance the structural integrity of the frame, the Elves have utilized the EPS and latex bladder molding process in the production of the Falath EXP. This advanced technique results in a smoother internal frame structure by eliminating folds, lines, and creases, ensuring more uniform walls and ultimately creating a stronger, more durable frame.

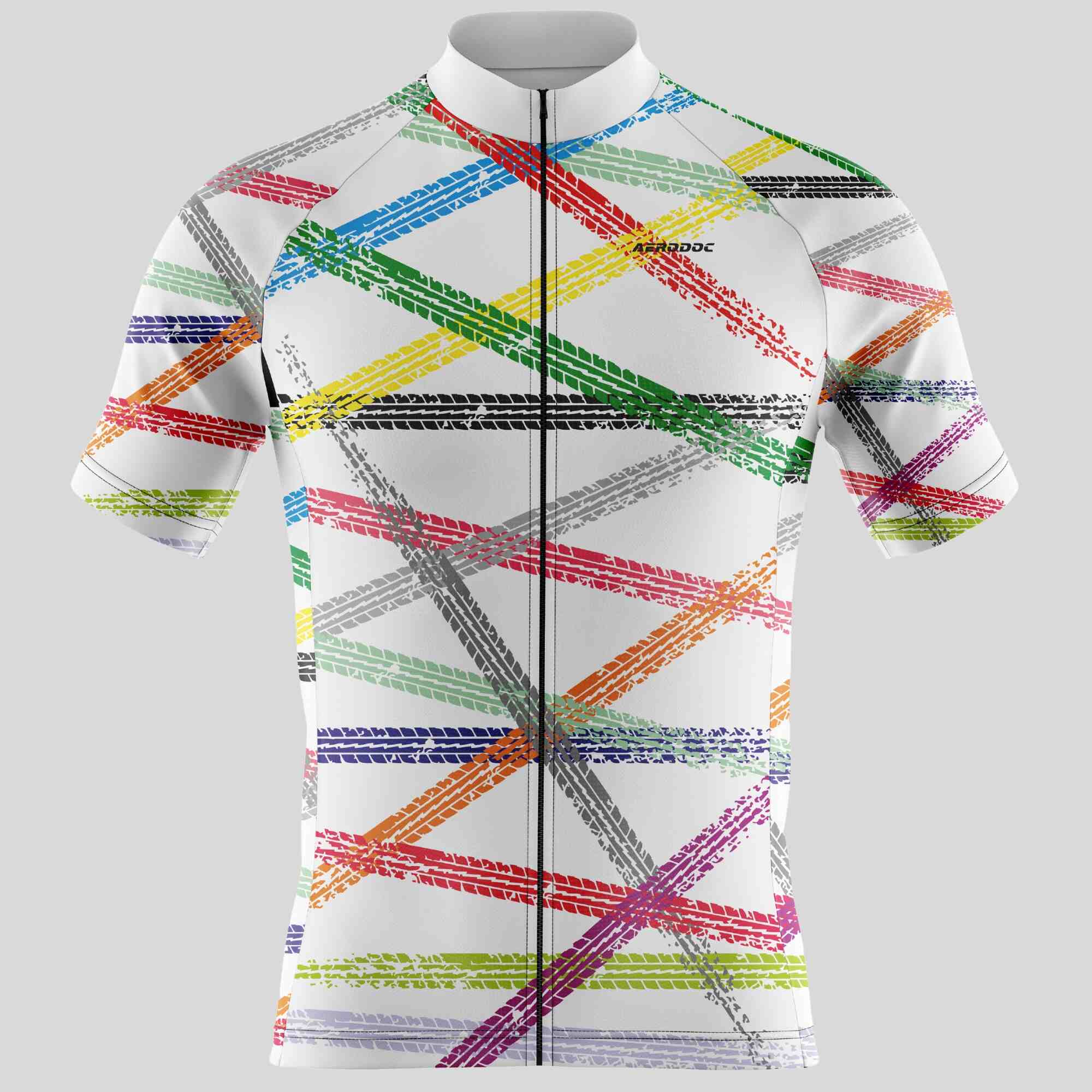

In collaboration with DSD, our design house in Hong Kong, and guided by invaluable customer insight, the Falath EXP 2025 debuts in seven modern colorways. Our philosophy is rooted in a deep understanding of unmet rider needs, which has shaped our commitment to accessibility and personalisation. As such, custom-painted frames, which remain at the heart of our vision, will be available for no additional cost.